BORN OUT OF NECESSITY

Our founding engineers led thermal management at large aerospace companies and couldn’t find the solutions they needed to build next-gen aerospace platforms. So, they decided to build it themselves.

We’re a team of engineers, technologists, designers, mathematicians, and problem solvers committed to a singular idea: reviving the no-boundaries mentality in aerospace. We grew up inspired by Charles Lindbergh, Amelia Earhardt, and Neil Armstrong, and we want to play a role in enabling a new generation of giant leaps for mankind.

We’re headquartered in St. George, Utah, a beautiful town nestled in the red sands of Southern Utah between Salt Lake City and Las Vegas. Our unconventional location allows us to keep overhead costs low and attract remote talent from around the country. It’s also just an amazing place to live and work — come visit and see what we mean.

Team

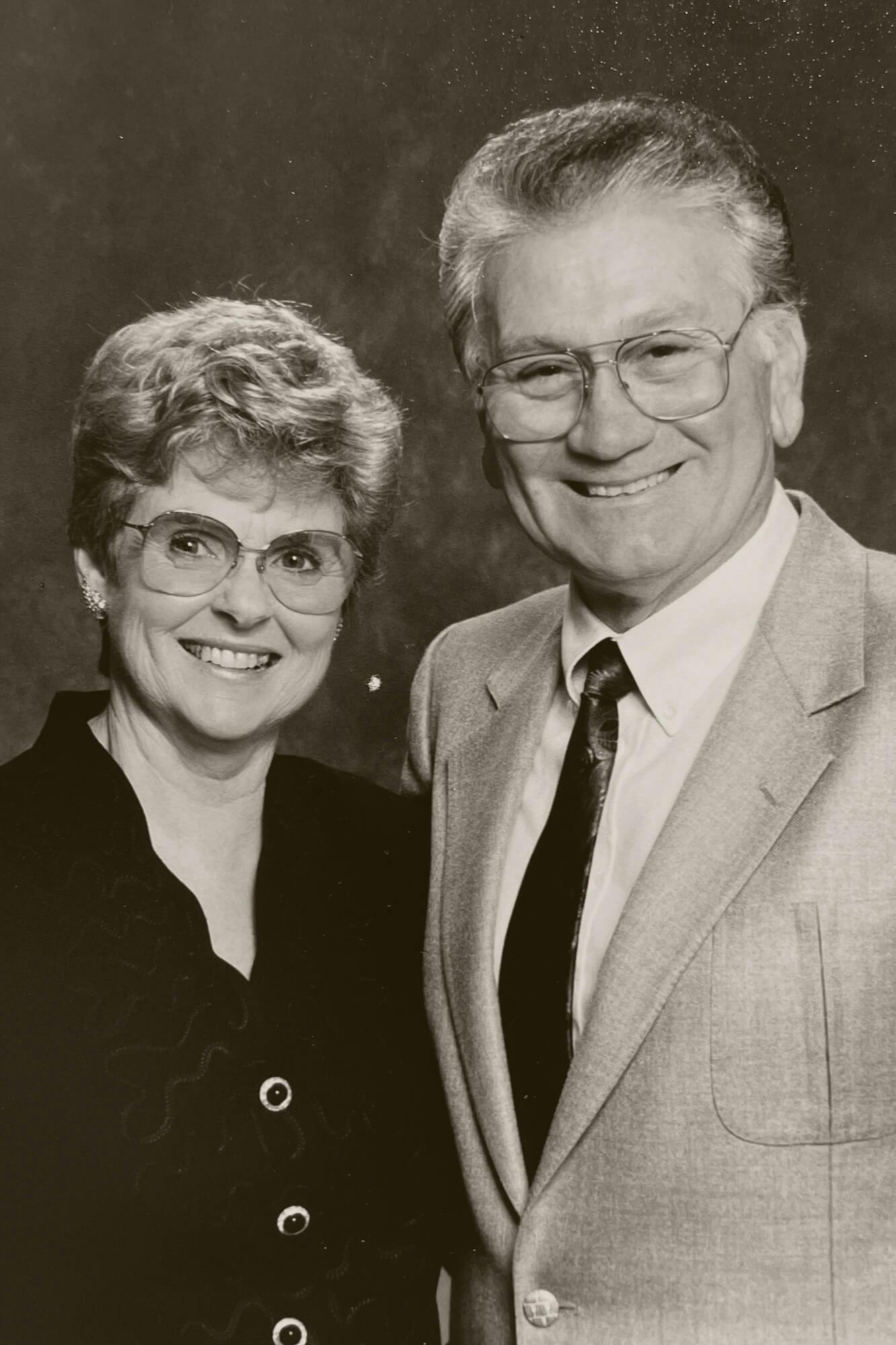

MELZIE & RAY GANOWSKY

CO-OWNERS

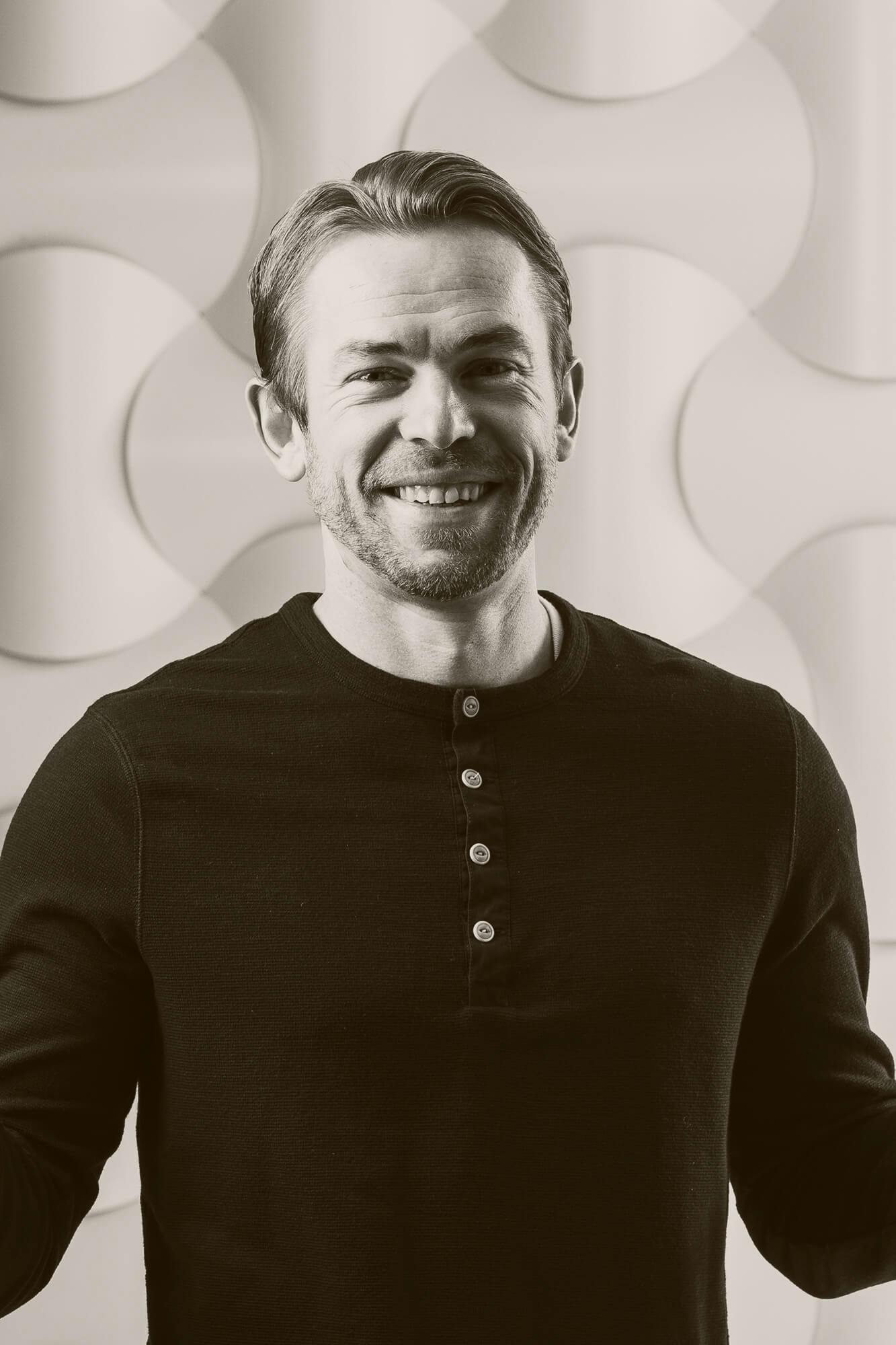

BRIAN MCCANN

CEO

Gary Stone

Chief Operating Officer

NICK KAISER

Chief Technology Officer

BRAD PLOTHOW

Chief Growth Officer

Sarah Pierce

Executive Administrator

KEVIN KERLIN

VICE PRESIDENT OF OPERATIONS

Ben Bryan

VP of Engineering & Head of Space Systems

Grant Bagby

Director of Finance

Tim Dutson

Director of Quality & Compliance

BECOME AN INTERGALACTIC RECRUIT

We’re building a crew of the nation’s best, regardless of where you live. Come join us at Intergalactic HQ in Southern Utah, or stay where you are and work remotely. We’re always on the hunt for top-tier engineers, designers, technicians, business specialists, and more.

Think you’d be a good fit? Take a look at our core values and drop us a line if this sounds like you.

CORE VALUES

The fuel that propels us onward, upward and beyond.

Impact

An insatiable appetite to go big.

Humility

It’s about getting it right, not being right.

PRECISION

Thorough and detail-obsessed because every-little-thing-matters.

FUN

Serious work can still be enjoyable.

INVENTION

We reverence and protect a culture of discovery and innovation.